How Can Sustainable Lightweighting Help Decarbonise the Automotive Industry?

October 9, 2023

Embracing Bcomp’s sustainable large-scale mobility solutions can enable up to 50% weight savings and up to 70% plastic reduction vs. conventional solutions.

News, customer cases, and anything else we hope you might find interesting. Scroll or search by tags.

October 9, 2023

Embracing Bcomp’s sustainable large-scale mobility solutions can enable up to 50% weight savings and up to 70% plastic reduction vs. conventional solutions.

ampliTex™ Automotive & interior panels Mobility Natural fibre powerRibs™

October 3, 2023

AK Durable Supply Co. has just introduced their new Method RS harness with FlaxFusion construction featuring ampliTex™

ampliTex™ Customer highlights Kitesurfing Natural fibre Play Naturally Smart Sports

September 26, 2023

Bcomp’s ampliTex™ natural fibre reinforcements make a prominent entry into the Duotone kiteboard lineup for the 2024 season.

ampliTex™ Customer highlights Kitesurfing Natural fibre Play Naturally Smart Sports

September 5, 2023

The SuMoth Challenge 2023 was a full success with more teams, more boats and more natural fibre applications than ever.

ampliTex™ Marine Natural fibre News Play Naturally Smart powerRibs™

July 25, 2023

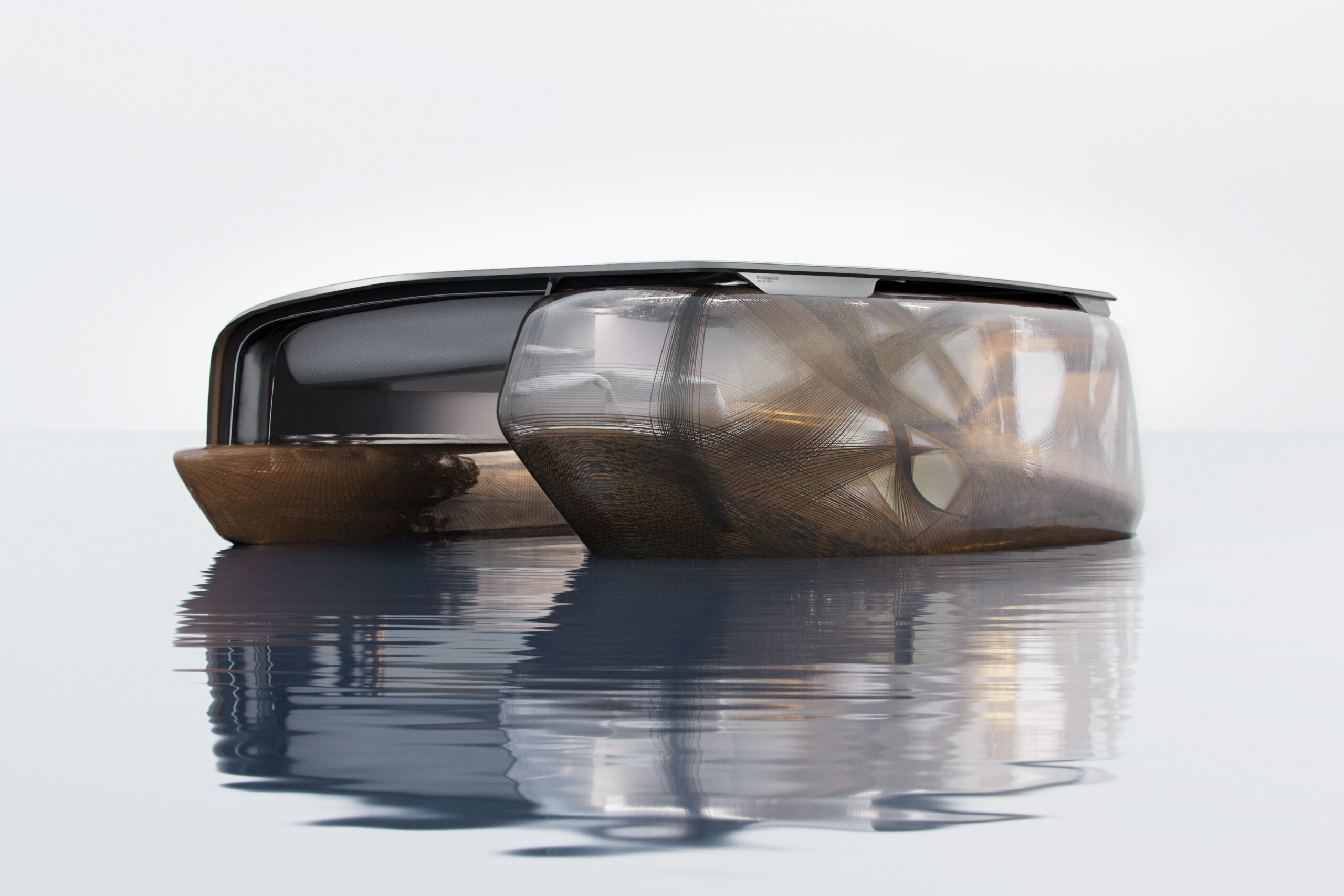

The ‘Blue Nomad’ floating concept habitat uses Bcomp’s ampliTex™ flax fibres to explore a new way of living on water.

ampliTex™ Customer highlights Design Infrastructure Lifestyle & society Natural fibre

July 17, 2023

With the ecoracer30, Northern Light Composites launched the world’s first recyclable production boat at The Ocean Race Grand Finale in Genoa.

ampliTex™ Customer highlights Marine Natural fibre Northern Light Composites Play Naturally Smart

July 10, 2023

Team Würth TRD Hilux MSB Tras 135 is competing in the 2023 AXCR with a custom made Bcomp natural fibre bodywork on their Toyota Hilux.

ampliTex™ Bodywork Customer highlights Motorsports & bodywork Natural fibre powerRibs™

June 22, 2023

Custom LiveWire ONE motorcycle “Silent Dancer” features full natural fibre bodywork made from Bcomp’s ampliTex™ reinforcements.

ampliTex™ Customer highlights Motorsports & bodywork Natural fibre

June 12, 2023

Volvo Cars’ EX30 marks another breakthrough for Bcomp as the first production vehicle to come with our natural fibre composite interior solution – and it can be ordered from today.

ampliTex™ Automotive & interior panels Customer highlights Mobility Natural fibre News Volvo Cars

May 25, 2023

McLaren Racing just published their latest sustainability report and shows that natural fibre composites are part of the future of F1 cars.

ampliTex™ Customer highlights McLaren Racing Motorsports & bodywork Natural fibre News powerRibs™

Dec 19, 2023

The Future of Automotive DesignIn collaboration with Polestar, the Swiss company Bcomp has developed a fabric that will not only transform the interior of vehicles but also reshape our notions of luxury and design sustainably. Ross Kelk from Polestar's development department and Per Mårtensson, CRO of Bcomp, spoke at the Polestar Space Zurich about the joint journey from vision to market readiness. It's hard to imagine how a bundle of flax sitting in the corner can become an ultra-light, futuristic-looking interior material. The technology of the Fribourg-based company Bcomp, founded in 2011, makes this possible. The so-called Polestar Signature Weave combines a smooth surface with a grid-like structure on the back. The result is an adaptable but very robust material that will be used in various interior trimmings of the Polestar 3, such as in the seat backs. Compared to conventional plastic trim, this can save more than half of the petroleum-based raw materials. Additionally, the material shines with its unique lightness, and reduces vibrations by up to 250 percent. A Shared Mindset "Natural materials are extremely efficient when used and applied in the right way," says Per Mårtensson, Chief Revenue Officer of Bcomp. Flax is an easy-to-care-for and highly robust plant that has been used as a raw material for linen in the textile industry for millennia. Today, more than 80 percent of the global flax crop is cultivated in Europe. Bcomp's origins lie in skiing, where the innovative flax fabrics helped increase performance and reduce the weight while decreasing the use of petroleum-based plastics. "When we first saw the material, we knew that this technology perfectly aligns with Polestar's goals," recalls Ross Kelk, Head of Interiors R&D and Industrial Program Leader of Polestar's British development team. "Our companies shared the same goals, values, and a common mindset from the beginning." A New Aesthetic Initially, however, it was not clear how and where the material could be used. "We experimented, played, tried different things," Ross remembers. This applies not only to the material but also to the entire perception of luxury. "Traditionally, manufacturers associate it with exclusive materials like leather, veneered wood, and a lot of embellishments. However, we wanted to confidently place the material in the foreground and openly showcase it. Make sustainability a tangible, exclusive experience." Thus, the design team sought a new aesthetic that makes this fusion of design, minimalism, and sustainability palpable. Sustainability inspired the design team to a completely new aesthetic. From Prototype to Frozen Pizza From the handshake to the first finished product took several years. The path from the prototype to mass production is full of challenges. "On the one hand, natural materials always vary — no cherry wood table is the same as another," explains Per. "Here, we had to reconcile variation and quality." On the other hand, any change in the manufacturing process of a vehicle entails costs and risks. "Polestar fully supported our joint idea, convinced suppliers and partners, and integrated the new material into the production chain." Per compares the current process (admittedly somewhat simplified) to a frozen pizza: "We deliver the jointly developed base material for the Signature Weave to production. There, it is heated and shaped." The Next Generation Unlike a frozen pizza, the development phase does not end with the first market-ready product. "Usually, creative work is done when a new technology is introduced into the production process. In our collaboration, it's different: we use insights from the production process for new creative approaches and ideas. We think in generations, so to speak," says Ross. Several new applications are already being tested, performance and sustainability are being optimized, and the idea of a circular economy is gaining more focus. "Recycling will be a significant topic for us in the coming years. We have already proven it is feasible in small scale. but the infrastructure for large scale recycling is still missing," says Per. The beginning of another joint step into the future? We'll see... Discover more https://www.polestar.com/de-ch/news/polestar-and-bcomp-future-fabric/ All images © Polestar - Kai Grossmann Have a question or want to stay in touch? Contact us now

Nov 17, 2023

Polestar Day 2023“Today is about giving you unique insight into the work that we have been doing in collaboration with our partners. We want you to leave with a sense of inspiration and excitement for what lies ahead.” - Thomas Ingenlath, Polestar CEO At the historic Barker Hangar in Santa Monica, Los Angeles, Polestar spoke with guests and the media to celebrate its passion for design, innovation, sustainability, and performance – showcasing what comes next for the Swedish brand. Bcomp played a crucial role in the event, which included an address from our very own Per Mårtensson, Chief Revenue Officer, who explained the history of the partnership, the potential of flax as an alternative to conventional engineering materials, Bcomp’s race-to-road evolution, and how we are industrialising Bcomp technologies for premium road cars. Four zones occupied the hangar, each associated with a different aspect of Polestar’s vision and aligned with one of its vehicles. Bcomp was present in the Polestar 3 Zone, highlighting its natural fibre performance composites that are seeing increasing adoption in automotive applications. Maximilian Missoni, Head of Design, Polestar, said: “We understood the huge potential of this material and, finally, after years of development together with our suppliers – and Bcomp – we’ve found the key to applying it in high volume production. Our own signature weave brings a luxurious and technical finish to this natural fibre composite, which means it can now be used as a functional and visual material." “As you saw in Precept, we will proudly show this off in our cars. Taking the step into volume production means we have now unlocked the potential for more natural fibre composites in our cars. It leads to less than half of the fossil-based content compared to traditional premium solutions used in automotive interiors, and it reduces the CO2 emissions of these components by over 50 per cent.” Other sustainable technologies were also exhibited, including vehicle-to-grid (V2G) systems and extreme fast charging (XFC), which can provide 100 miles of range in just 5 minutes. Advanced Driver Assistance Systems (ADAS) were another area of focus, including radar, LiDAR, and camera-based technologies. Per Mårtensson, Chief Revenue Officer at Bcomp, commented: "A heartfelt thank you to Thomas Ingenlath and the entire Polestar team for an incredible event. We are honoured to contribute to Polestar’s successful journey towards sustainable mobility. This close partnership reflects our shared commitment to sustainability, quality, and performance." “Our joint efforts in satisfying demanding safety requirements, meeting Polestar customer expectations, and achieving scalable production solutions has been a masterclass in collaboration. Together, we've achieved a premium, modern, and elegant aesthetic for the Polestar signature weave, setting a new standard for excellence and a unique expression of sustainable modern luxury." Discover more Official news and video recap from Polestar https://www.polestar.com/global/news/polestar-day Watch the full keynote on YouTube All images © Polestar Have a question or want to stay in touch? Contact us now

Oct 25, 2023

Natural Fibre Composite Deco Parts for the Automotive IndustryWhat if you combine one of the most common production methods in automotive – fast, precise, cost efficient – with high-end natural fibre deco elements that both reduce environmental impact and offer unique design opportunities? Vernicolor teamed up with Bcomp to find out. The result – plug-and-play market ready back-injected deco parts for automotive interiors with Bcomp’s technical ampliTex™-PP fabrics – looks a stunner if you ask us! The ampliTex™ range offers unique design opportunities with colours and weaves. Readily available as a drop-in solution, ampliTex™-PP can be used directly in the most wide-spread production process for interior decorative parts. Thanks to the customisability of ampliTex™, different aesthetic surfaces can be achieved from a single existing tool. Therefore, ampliTex™-PP offers design freedom and ease of implementation. Furthermore, ampliTex™-PP has passed the strict UV & scratch resistance specifications of several OEMs and, unlike many other materials, does not need any additional coating. “Vernicolor is a pioneer in high-end decorative automotive parts, and it is an honour to collaborate with them to further develop our natural fibre solution for the wide market”, comments Nicolas Samson, Senior Sales Manager Automotive Interiors at Bcomp. “ampliTex™-PP is a drop-in solution that can easily be combined with back-injection moulding, making it compatible with the large-scale production technology most used by leading OEMs. This collaboration marks a big step for Bcomp in delivering our sustainable lightweighting technologies based on natural fibres to the full automotive market to maximise the benefits of lighweighting and sustainable materials across the entire industry.” Vernicolor is one of the leaders in decorated subassemblies, and supplies T1s and OEMs worldwide with top-quality solutions, offering a variety of production methods. The ampliTex™ deco panels will complement their offering with a new type of aesthetic and design opportunities. Bcomp is a Swiss company specialised in natural fibre solutions for sustainable lightweighting – seamlessly combining performance, sustainability with custom design opportunities. We are looking forward to continuing the collaboration! Have a question or want to stay in touch? Contact us now

Oct 09, 2023

How Can Sustainable Lightweighting Help Decarbonise the Automotive Industry?ampliTex™ and powerRibs™ are terms that are becoming ever more common in the automotive industry. Debuting in the motorsport industry, and being used by the likes of BMW, Porsche, as well as the McLaren Formula 1 team, Bcomp’s innovative natural fibre composite technologies are now taking the production vehicle industry by storm, already being featured in the likes of the new Volvo EX30. Embracing Bcomp’s sustainable large-scale mobility solutions can enable up to 50% weight savings and up to 70% plastic reduction vs. the common injection moulding (IMPP) solution. So, let’s see what ampliTex™ and powerRibs™ are really about and why they have become synonymous with high-performance natural fibre composites and sustainable lightweighting. The Advantages of ampliTex™ and powerRibs™ ampliTex™ is a cutting-edge, lightweight natural fibre reinforcement fabric that offers numerous benefits for the large-scale automotive industry. It is made available as different types of fabric from UD to biaxial and twills, all the way to customised weaves and can be had as prepreg or dry reinforcement for thermoset applications or more importantly as ampliTex™-PP – a ready-to-use thermoplastic material. Notably, it stands out for its ability to infuse a modern and natural aesthetic into the design of your components. With a wide range of customisation options, it allows for a multitude of looks and colours, adding a touch of personalisation and uniqueness to each vehicle. The natural material adds character and soul that shine where synthetic materials like carbon and glass fibres suffer from a dead perfection. powerRibs™ on the other hand draw inspiration from the supporting 3D structure of leaf veins. They represent a groundbreaking patented composite technology that delivers an unmatched stiffness-to-weight ratio while using minimal base material. They can be used to reinforce almost any composite shell structure and in combination with many different composite materials and manufacturing processes. Previous image Next image In automotive interiors, ampliTex™ can replace petrol-based materials, such as IMPP or traditional cover materials, which helps to reduce CO2 emissions during the production phase of a vehicle. It is compatible with standard production methods and, as a readily available drop-in solution, can simply be used in a traditional injection moulding tool to create a high-end part with a supreme visual quality directly from a one-step-process. When used in combination with well-established NFPP, ampliTex™ has significant weight reduction capabilities vs. the IMPP benchmark while providing a one-step production process that yields a high-end surface straight out of the tool. The aspect of lightweighting also helps reduce CO2 emissions produced during the use phase of the vehicle, as a lighter car consumes less energy to cover the same distance. powerRibs™-PP can either be used in combination with ampliTex™-PP and NFPP for a very lightweight mono-material solution or it can be used in conjunction with an NFPP layer and any standard cover material to provide lightweighting benefits even in areas that are not directly visible. Manufacturing interior components with the ampliTex™-PP and powerRibs™-PP technologies allows for up to 50% weight savings and up to 70% plastic reduction vs. the usual IMPP go-to solution. From the Fields of Europe to Your Everyday Vehicle The automotive industry stands among the largest contributors to global CO2 emissions. However, it's crucial to recognize that this environmental impact isn't solely limited to a vehicle's use phase. Indeed, a substantial portion of CO2 is emitted during both the production and the end-of-life stages of a vehicle's life cycle. Now, natural fibres composites, coming from flax plants that have been cultivated and used for centuries in Europe, could play a significant role in reducing the emissions and impact of the automotive industry. Previous image Next image Production Process The production process of a car plays a significant role in contributing to CO2 emissions throughout its entire life cycle. Material emissions and energy intensive manufacturing steps add up to what results in the largest chunk of emissions for a state-of-the-art electric vehicle. In comparison to conventional IMPP parts with traditional cover materials, the innovative combination of ampliTex™-PP, NFPP and powerRibs™-PP presents a solution that slashes the quantity of CO2 emitted from cradle to gate by up to 60%. Not only does the Bcomp technology have a substantial positive environmental impact, but it also delivers practical benefits for large-scale production. Easily integrated into existing production lines, it can simplify manufacturing by eliminating certain steps. Creating parts with a perfect visual surface directly out of the mould allows to forego additional steps like the application of traditional cover materials. The possibility of implementing a one-step back injection process for local reinforcements and fasteners further enhances efficiency, allowing the solution to comply with tight time restrictions in mass production settings. Use Phase Beneath the captivating, modern and natural aesthetic of ampliTex™ with its unique character lie the true sustainability benefits of Bcomp’s materials. Weight savings of up to 50% on part level unfold their full effect throughout a car’s lifecycle and use phase. Every gram that is saved in an interior component helps the vehicle to consume less energy to travel a certain distance thereby contributing to a substantially lower amount of CO2 emissions during its use phase, without compromising on performance. End of Life Now, more than ever, considering the end-of-life phase of products holds paramount importance. Reducing the plastic content in parts by up to 70% thanks to the benefits of our renewable material solutions is already a big step but we don’t stop there. Components made with a mono-material combination of ampliTex™-PP, NFPP and powerRibs™-PP can easily be converted into a new base material at the end of their useful life. Shredding components and compounding them into flax-PP pellets creates a new base material for injection moulding processes. This means that parts made with Bcomp’s thermoplastic ampliTex™ and powerRibs™ materials can be completely recycled and repurposed to serve a 2nd life in another set of components. Polestar Precept seat with ampliTex™ and powerRibs™ Using the Bcomp Solutions Bcomp offers a diverse range of adaptable and customised product solutions to cater to a wide array of needs. Beyond cutting-edge sustainable technologies, Bcomp provides strong support and guidance, ensuring the seamless implementation of Bcomp innovations in both vehicles and production processes. Sustainable Lightweighting Designing parts to be manufactured with a combination of ampliTex™-PP and an NFPP base layer or ampliTex™-PP, NFPP and powerRibs™-PP as an additional reinforcement, allows you to make the most of our sustainable lightweighting potential. Replacing conventional IMPP components with our large-scale natural fibre technologies allows for up to 50% weight reduction, up to 70% less plastic use in the component and up to 60% lower CO2 emissions from cradle to gate. Processing happens in conventional compression moulding machines with dedicated tools and Bcomp’s engineering team is here to support you with its expertise through the entire implementation from first idea to the final part out of press. Sustainable Design Where the sustainable lightweighting concept is focused on exploiting the full potential of Bcomp’s ampliTex™ and powerRibs™ technologies, the idea of sustainable design combines sustainability benefits with a desire for unique aesthetics. The character and soul transmitted by the natural appearance of ampliTex™, is combined with the simplicity of an injection moulding process. Used as a customisable visual layer, ampliTex™ can replace traditional petrol-based cover materials with a renewable alternative while guaranteeing highest ease of use as a drop-in layer in your injection moulding process. This simple compatibility with one of the most widely used production processes, really allows OEMs and Tier 1s to easily embrace the sustainable design perks of ampliTex™ without having to worry about added complexity. With a variety of weave and colour options, ampliTex™ is guaranteed to fulfil your wishes for sustainable design options. And with the possibility to completely customise and tailor our beautiful natural fibre composites to customer needs, your imagination is the only limit between you and the future of sustainable interior design. Have a question or want to stay in touch? Contact us now

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.