“For the first time since carbon fibre entered the motorsport market 37 years ago, there is an alternative material for bodywork, and clearly a step to prepare motorsport for the future and to attract new generations.”, said Wiliam Kimberley, RACE TECH Editor-in -chief, at the World Motorsport Symposium 2018. Bcomp’s solution for replacing carbon fibres with powerRibs™ reinforced ampliTex™ natural fibre composites is live in some of the largest racing series and have proven their place on tracks around the world for seasons.

High performance

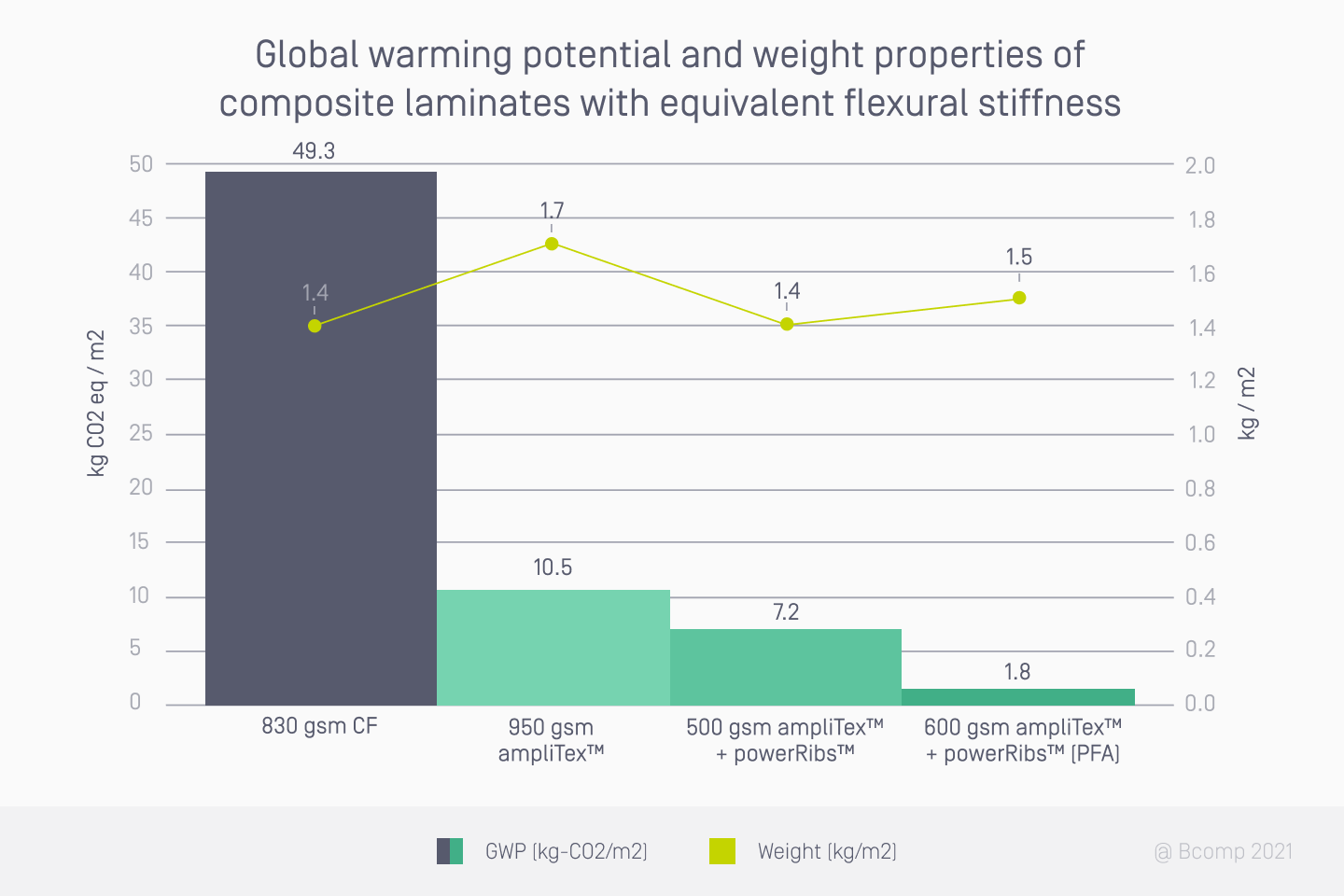

Matching stiffness and weight of thin-walled monolithic carbon fibre parts

Improved safety

Ductile fracture behaviour and blunt edges, no toxic carbon fibre dust

More sustainable

85% lower CO2 footprint from cradle to gate, end-of-life thermal energy recovery

Bcomp’s solution for sustainable lightweighting in motorsport has been awarded the Most Innovative New Motorsport Product by the World Motorsport Symposium, the Product Showcase Awards by Autosport International and was a JEC Innovation Awards finalist together with Porsche AG for serial production of natural fibre bodywork for racecars.

The products are used in more than 16 racing series around the world, from GT to Formula and Rallye. Bcomp is technical partner for sustainable lightweighting of the DTM and collaborates with Porsche customer racing team Four Motors as well as Aston Martin customer racing team Optimum Motorsports, who are both racing with Bcomp’s solutions.

In addition to racing series, several high-attention-projects such as the Gillet Vertigo for Pikes Peak, Electric GT racing adapted TESLA, and the ALTER by DAB Motors for YAMAHA all have ampliTex™ and powerRibs™ bodywork.

© BMW Motorsport

BMW has launched their new M4 GT4 with ampliTex™ and powerRibs™ flax fibre solutions throughout the interior as well as on several bodywork components. BMW's commitment to the extensive use of sustainable composite solutions results in the new M4 GT4 sporting more natural fibre components than any other GT racing car in series production. Taking the findings and experience gained on the track as a basis, these new material technologies will also find their way into BMW M models, and BMW M Performance Parts, as stated by BMW Group.

The new BMW M4 GT4

© McLaren Racing

We are extremely proud and excited to collaborate with McLaren Racing on pioneering the use of #sustainablelightweighting in Formula 1.

McLaren Racing seat made with ampliTex™ and powerRibs™ technologies

© Porsche AG

With sustainability ever higher on the agenda, Porsche Motorsport launches 718 Cayman GT4 CS MR featuring a full natural fibre bodywork kit developed with Swiss firm Bcomp.

Porsche 718 Cayman GT4 CS MR with full flax fibre bodywork

© QEV Technologies

Spark's all-electric race SUV for the Extreme E features natural fibre bodywork using Bcomp's ampliTex™ and powerRibs™ technologies.

The Spark Odyssey 21 with natural fibre bodywork

Thanks to the powerRibs™ technology, a full-natural fibre layup of ampliTex™ + powerRibs™ matches the stiffness and weight of a monolithic carbon fibre part for motorsport bodywork and other thin-walled shell elements. As opposed to carbon fibres, this natural fibre composite has a ductile fracture behaviour with blunt edges, thus improving safety without sharp carbon fibre shattering and toxic carbon fibre dust. Furthermore the vibration damping is significantly improved.

The production of parts made from ampliTex™ and powerRibs™ has a 85% lower CO2 footprint than that of carbon fibre parts with equal weight and stiffness performance. Furthermore, as no bleeders and breathers are needed, production consumables are reduced, reducing both costs and waste. At the end of their life, parts can be used for thermal energy recovery without residual waste in the standard waste management system. Carbon- and glass fibres on the other hand sadly often end up in landfills.

Bcomp offers both dry fibres and high-quality natural fibre prepregs from trusted partners. Thermoset production can be done using vacuum infusion, autoclave, prepreg compression moulding (PCM) or RTM in the same molds as for carbon fibre parts. The Bcomp engineering team provides optimisation of layups and can perform reverse engineering of existing carbon fibre parts to facilitate implementation. We support our clients all the way to the final parts.

With the ampliTex™ and powerRibs™ product ranges, we offer solutions for sustainable lightweighting from sports to space.

The ampliTex™ and powerRibs™ product ranges of natural fibre reinforcements for sustainable lightweighting.